The choice of materials to be used for the construction of the safety shoes must be dictated by the technical characteristics, as well as by the aesthetic criteria.

Find out in this article what are the 7 indispensable components to use for work shoes.

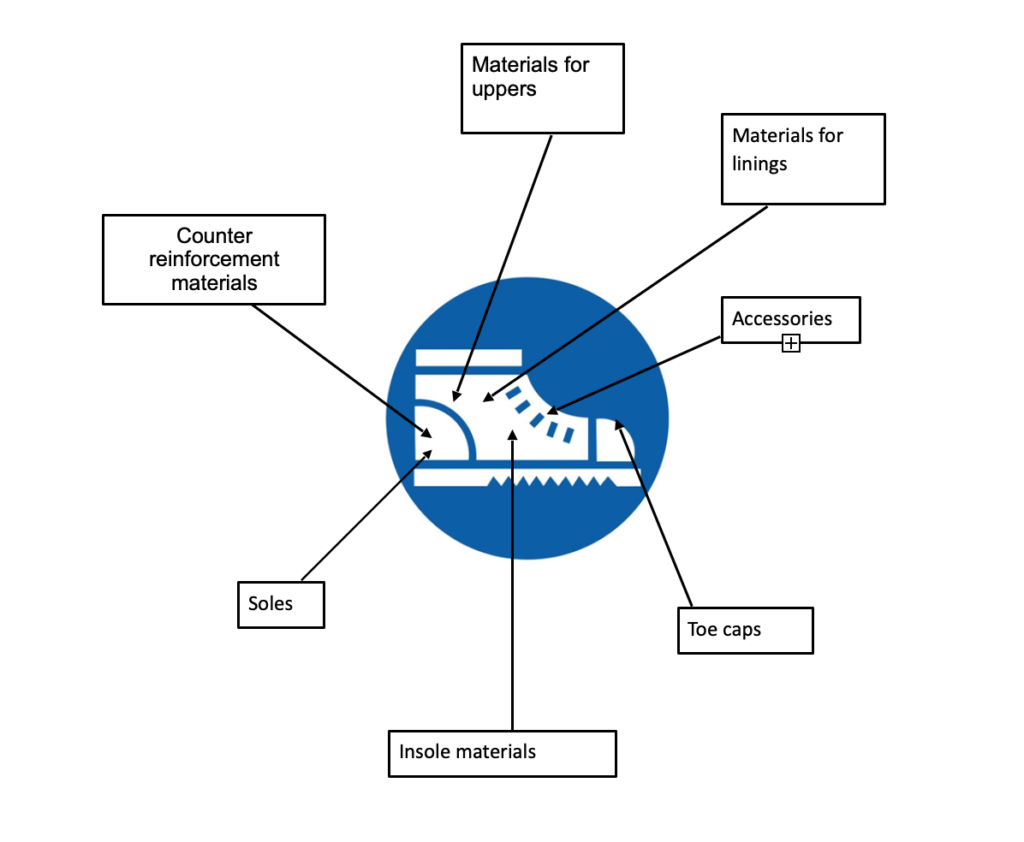

Let’s start with the first question: how is a work shoe composed?

We show it to you in this short illustrated infographic.

The safety shoes are specifically designed to protect the foot from possible accidents while carrying out some jobs where there are dangers of perforation, crushing, burns and caustication.

They are used in heavy and light industry, in maintenance work, in hospitals, in catering and in other sectors where it is important to protect our feet.

Depending on the work environment in which they are to be worn, they must comply with the specific requirements laid down by each legislation.

What are the main characteristics?

The safety shoes must have the following characteristics:

– Non-slip;

– Self-extinguishing;

– Antistatic;

– Waterproofing of the upper;

– Anti-perforation;

– Cut resistance of the upper;

– Hot/cold insulation;

– Electrically insulating (dielectric);

– Sole resistance to hydrocarbons;

Now let’s find out in detail what are the 7 essential materials for professional work shoes.

1) REINFORCEMENT MATERIAL FOR COUNTERS

To give shape and greater rigidity to the back side of the shoe. The most suitable materials for the safety shoes are:

– Leatherboard

– TNT

– Thermoplastic material

2) INSOLE MATERIALS

Sheet materials from which the insoles for the inside of the shoe are obtained. Depending on the material used, the shoe acquires different characteristics and degrees of protection. Among the most suitable materials we find:

– Anti-perforation material

– Steel

3) TOE CAPS

The rigid protective toe caps are applied between the lining and the upper and have the purpose of protecting the toe from crushing due to impacts and accidental fall of weights. The most suitable tips are made of:

– Metal

– Composite material

– Carbon fiber

4) MATERIALS FOR UPPERS

External coating of the shoe both on an aesthetic level (choice of colors, textures, etc.) and functional (to create breathable, waterproof, acid, fire and cut protective shoes). Among the various materials for uppers the most suitable are:

– PU coated leather (BY CAST)

– Upper-resistant material

– NO CUT (a fabric called “bridle effect” allows you to block sharp blades)

5) LININGS

Internal lining of the shoe that guarantees comfort and functionality. In fact, linings for work shoes can be:

– Breathable

– Waterproof

– Antibacterial

– Resistant to hot/cold temperatures

– Resistant to fire

– Comfortable in the use of the footwear

6) ACCESSORIES

Accessories to complete and finish the shoe, such as:

– Lace hooks (self locking, with rivet closure o quick release)

– Laces

7) SOLES

An indispensable element of the safety shoe as in contact with the ground it has an anti-slip function, electrical insulation and eventual resistance to high temperatures.

The soles are usually produced in polyurethane material, thermoplastic material or rubber (nitrile).

The commonplace that safety shoes are uncomfortable for prolonged use has been dispelled in recent years thanks to new technologies that make the shoe more comfortable and lighter.

In addition, models and styles have also undergone an important evolution, making these shoes more pleasing from an aesthetic point of view.

Are you interested in having more information about the most suitable materials to be used to produce safety shoes?

To request the catalog of the materials we have available, write to: info@taigaitalia.eu